We are southeast Wyoming’s number one full-service ski and snowboard shop!

Whether you need a quick wax, full tune, adjustment or intensive repair on your downhill skis, nordic skis, snowboard, or anything between, we can get you back on the snow with confidence.

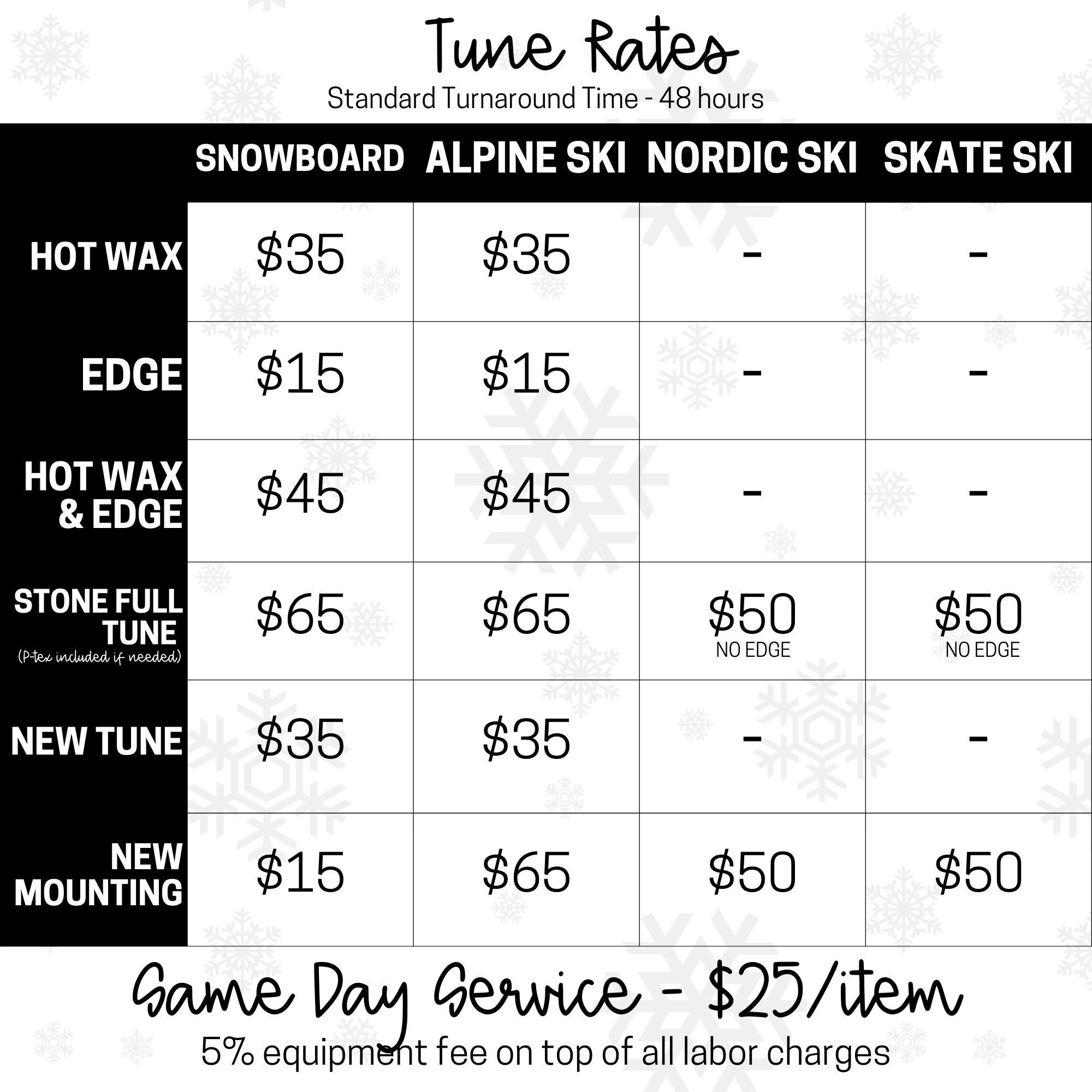

Below is a partial list of our tuning & adjustment services; if you don’t see what you’re looking for here, give us a call or stop by the shop any time for an estimate.

We recommend waxing your equipment regularly–multiple times per season, in fact. This not only improves performance very noticeably, but also keeps the base of your board(s) in proper condition throughout the year. And when the inevitable scratches & gouges show up in the base, we can smooth & patch them to keep you gliding effortlessly.

Similarly, the metal edges of your skis or snowboard should always be sharp, smooth, and rust-free to ensure reliable control over your every move. We use state-of-the-art machinery to get perfectly sharp edges every time, and deburr afterwards to ensure smooth performance.